Managing our Waste

- The Industry and our Footprint

- This is our Non-Financial Performance

- WBCSD/CSI

- GAEA Case

- Partnering for a country without waste

In today’s environmentally conscious global community, the reduction, reuse and recycling of raw materials, energy and waste are the cornerstone of any industrial activity. The requirements of sustainable development in a world with constantly growing demand have lead all sectors of industry, and the cement industry in particular, to act immediately and intelligently.

The reduction, reuse and recycling of raw materials, energy and waste constitute a primary element in the implementation of the Group’s environmental policy both at the tactical and the strategic levels.

In order to achieve these targets, all of the TITAN Group facilities have developed and implemented, or plan to implement in the near term, 3R practices.

Raw materials and intermediary products, which leak out of the production process, are recovered, as far as possible, with specialized equipment and, after they are appropriately processed to remove foreign particles, are reintroduced into the production line and subsequently reused.

As part of our policy for sustainable development, wastes produced as part of our everyday activities are collected, stored and disposed of through authorized contractors. TITAN is, furthermore, a founding member of the Hellenic Recovery and Recycling Corporation (EEAA). Most of our sites have a management system for wastes that is part of the ISO14001 or an equivalent system, wherever such a system exists. Among the materials thus collected are iron and aluminum scrap metals, vehicle batteries, used lubricants, used tires, electrical, electronic and electric equipment, paper, cardboard, household batteries, and toner used in printers and photocopiers. It is important to understand that the proper disposal of such materials can be a very challenging effort in certain countries like Egypt, Turkey or Albania, that the network of waste collection is underdeveloped or limited and in many cases is lacking the support and monitoring of local authorities. There are occasions when we have to store these materials at our sites until a certified waste recycling contractor can undertake the collection and appropriate disposal of certain wastes.

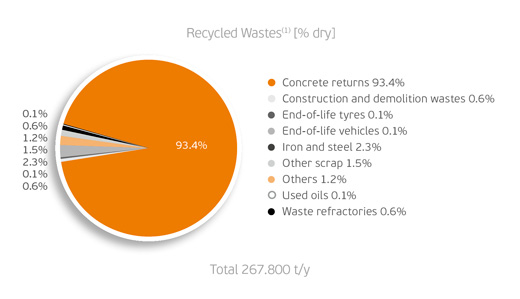

Recycling of wastes is a win-win practice that serves the goal of reducing our impact on land by minimizing the need for landfilling as well as the use of extracted raw materials. Compared to 2011, the recycled quantities of wastes have increased by almost 60.0%. Concrete recycled accounts for more than 90.0% of the total amount, having increased by almost 70.0% since 2011..The implementation of a better monitoring system, developed under the “Green-Star” program that our ready-mix facilities in the U.S.A. are part of (which keep a daily track record of concrete returned back to each plant) resulted in more accurate record keeping and was a contributing factor to the observed increase.

| Recycled waste | |

| 2012 | |

| Concrete returns (ready mix units) | 250.070 metrict/year |

| Construction and demolition wastes | 1.695 metrict/year |

| End-of-life types | 280 metrict/year |

| End-of-life vehicles | 360 metrict/year |

| Iron and steel | 6.235 metrict/year |

| Other scrap (excluding iron, steel, aluminum, some cables) |

4.070 metrict/year |

| Others | 3.171 metrict/year |

| Used oils (engine, gear, and lubricants) | 300 metrict/year |

| Waste refractories | 1.620 metrict/year |

| Total | 267.800 metrict/year |