Environmental Performance

Pledges and commitments

undertaken by TITAN Group in line with its values, Code of Conduct and priorities:

Global Compact (UN Declaration of Human Rights, ILO Conventions)

WBCSD/CSI (sectoral initiative)

ISO 14001, ISO 9000, OHSAS 18001, SA 8000 (norms and equivalent local standards)

EU strategy 2011-14 for Corporate Social Responsibility (Oct. 2011)

In 2012, TITAN Group produced 12.9 million tons of cement at its 13 operating cement production facilities and three cement grinding plants. The nine production units of Separation Technology produced about 1.0 million tons of cementitious material.

Compared to 2011, Group performance presented varied trends. Some areas, like dust emissions, water consumption and alternative fuels usage were significantly improved, while other areas, like CO2 emissions, presented deterioration.

Our specific dust emissions decreased by almost 50.0%, achieving and actually exceeding the Group target as a result of investing heavily in new technologies in the form of bag filter systems to reduce our air emission footprint. Similarly, investments in water recycling systems and improvements of existing water networks have led to efficient use of water, while the development and implementation of water management systems in our operations improved monitoring and reporting of water use and consumption. Specific water consumption of cement plants was decreased by 14.0% compared to the previous year succeeding in remaining below the Group target.

The consumption of alternative fuels almost doubled compared to 2011 levels. This is a result of the greater than ever use of alternative fuels by all of our plants that are using such fuels. In the last few years, cautious but ambitious plans were prepared and put into action. As part of those plans, investments on fuel preparation facilities as well as new and upgraded facilities for handling, storing and feeding alternative fuels were made.

On the other hand, specific CO2 emissions increased by about 6.0% compared to 2011, moving away from the Group target set. Over the last several years, we have increased our efforts to expand the use of alternative fuels and reduce the thermal energy consumption of our facilities. However, due to prevailing economic conditions we were forced to operate in markets characterized by low penetration of blended cements. As a result, the average Group clinker-to-cement ratio increased, having a negative effect on our specific emissions footprint.

In 2012, our cement plant in Albania obtained its ISO 14001 certificate helping us to achieve our target of certifying all of our wholly owned (in 2009) cement plants according to that standard. In addition, an Environmental Impact Assessment Study (EIAS) and a Rehabilitation Plan (RP) was developed for the SuvoVrelo limestone quarry in Serbia, thus increasing the relevant Group-wide coverage indicator to 63.0%. Finally, the development of a water management system has almost been completed, covering the corporate level, all of our cement plants and most of our ready-mix plants. A period of 1-2 years is required for its full implementation, especially for the large number of widely distributed ready-mix plants.

Group Envinonmental Performance 5-year Key Figures

| 2008 | 2009 | 2010 | 2011 | 2012 | |

| Gross direct CO2 specific emissions (kg/tProduct) | 649.4 | 633.8 | 654.2 | 623.8 | 658.7 |

| Total heat consumption, TJ | 42,924 | 37,257 | 43,155 | 36,828 | 41,152 |

| Total alternative fuels, metric tons | 21,160 | 30,570 | 32,290 | 30,630 | 68,050 |

| Specific water consumption (lt/tCement) | 569.3 | 447.8 | 362.3 | 340.1 | 300.0 |

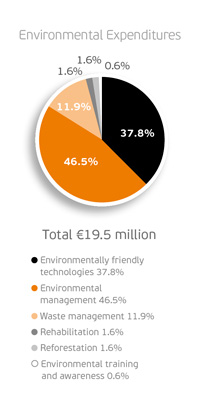

| Environmental expenditures, million euros | 26.6 | 22.5 | 27.1 | 36.6 | 19.5 |

Having succeeded in achieving many of our targets, it is now time for us to re-evaluate our status and think about our future commitments. In the coming year, we will revisit our targets and, based on our current performance, our environmental strategy, our obligations towards stakeholders as well as the anticipated business environment, we will once again set the benchmarks of our future path.

It should be noted that at all cement plants and adjacent quarries, internal audits are performed by the plant Environmental Managers in accordance with the ISO 14001 requirements and frequency. These audits fully cover environmental compliance with permits, air emissions - including CO2 emissions, water, raw materials, fuels and wastes. In addition, CO2 emissions audits by external verifiers are also performed each year at all Greek cement plants and at Zlatna Panega, as per the relevant regulation of EU/ETS. Moreover, our Group Engineering and Technology Department has the responsibility of performing environmental audits as part of our commitment to carry out such audits at each one of the wholly owned cement plants every three years. Although no audits were performed during 2012, due to resource constraints along with an unexpected stoppage of SharrCem plant in Kosovo that was scheduled to be audited, it is in our plans to restart auditing our facilities, even at a slower pace, as soon as conditions permit.

This part of the 2012 Report includes consolidated data from our cement production and cement grinding plants and their attached quarries as well as three quarries that, although not attached to a specific cement plant, provide raw material only to Group cement plants.

It is important to note that:

1. Presented data related to raw materials and energy consumption is calculated based on the equity held by TITAN Group in each specific year.

2. Performance related indices that are connected to a Group target, like specific air emissions for CO2, dust, NOx and SOx, specific water consumption as well as alternative fuel substitution rate are calculated based on the equity held by TITAN Group in 2009.